Learning Objectives

* After completing the PLC training, participants will be able to:

* Specify PLC control hardware and installation criteria

* Describe PLC software structure

* Write basic level PLC programs (using ladder logic)

* Use programmable logic controllers to solve machine and process problems.

* Troubleshoot a typical PLC control system

Course Content (4-day)

1. Introduction

* Introduction and brief history of PLC controls

* Alternative control systems - where do PLCs fit in?

* Why PLC control has become so widely accepted

* Lingering concerns about PLC control

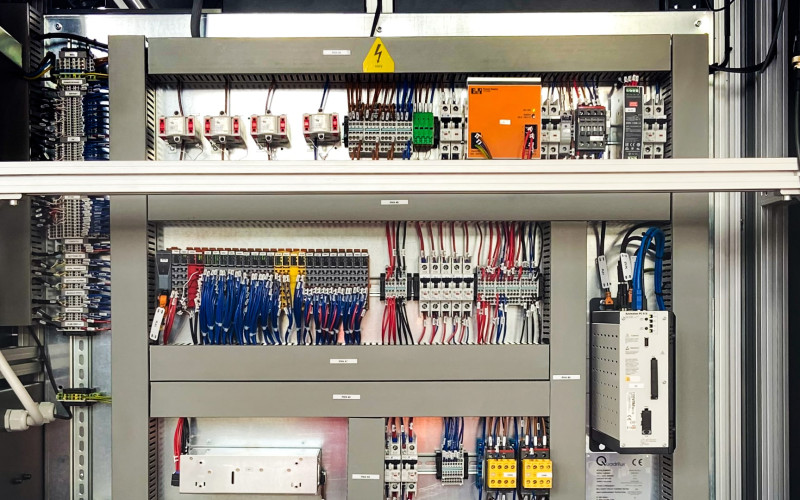

2. Fundamentals of PLC Hardware

* Block diagram of typical PLC

* PLC processor module - memory organization

* Input and output section - module types

* Power supplies

3. Selection, Installation & Safety

* Follow our 11 major steps in selecting a PLC for an application and avoid using the

wrong controller Install sinking and sourcing inputs and outputs properly?one wrong wire and it won?t work

* Implement safety circuits correctly in PLC applications to protect people and equipment

* Prevent noise, heat, and voltage variations from ruining your PLC system

* Implement a step-by-step static and dynamic start-up checkout to guarantee smooth PLCsystem operation

*Design preventive safety and maintenance into your total control system

4. Troubleshooting & Maintenance

* Learn troubleshooting procedures to reduce downtime

*Troubleshoot analog I/O and avoid undesirable count jumps

* Learn 6 preventive maintenance procedures to keep your PLC system running fault free

* Learn a step-by-step procedure for finding hidden ground loops

* Learn how to deal with leaky inputs

* Identify vibration problems and use them for preventive engineering control

* Control excessive line voltage and avoid intermittent shutdowns

INDUSTRIAL CONTROL & AUTOMATION (PLC)

Newsletter - Get Updates & Latest News

Get in your inbox the latest News and Offers from