Below is our various Training Programs

Services

Training

Energy Management

MemCons energy management specialize in educating, evaluating and recommending energy saving management solutions to our clients in industrial. Commercial and institutional sector.Our services includes*Energy Audit*Energy Analysis*Energy Saving Management Solutions*Education on Current Best Energy Saving Measures

Spare parts and Materials Management

Spare Parts Management and an organized maintenance storeroom is one of the key processes which support effective maintenance planning & scheduling and equipment reliability improvement. Improved materials management and spare parts management will free up time for maintenance planners, maintenance supervisors, and hourly maintenance personnel.

Root Cause Problem Elimination

This is the strategic art of choosing problems to eliminate, eliminating the problem and then educating and training all who are involved.We currently offer the following in problem solving, they are:* Problem Solving training for the Maintenance Technicians/Engineers* Lead/ Facilitate a Problem Solving training

Preventive Maintenance/ Essential Care and Condition Monitoring (PM/ECCM)

PM is the foundation of the entire maintenance philosophy. As a Key for all Maintenance and Production Personnel, unless the PM is effective, all subsequent maintenance activities will:*Cost more than they should to implement* Take longer than they should to implement* Have a higher probability of failure

5S KEYS (5S)- Keys to Total Quality Environment

5S provides the foundation for all improvement initiatives and helps to establish a culture ofcontinuous improvement. While implementation of 5S will result in a cleaner, betterorganized work place it will also allow your organization to:

Current Best Practices (CBP)

CBP is a collective functioning and concurrent application of changes in both the technology and management of the organization. For the cycle of change to be sustained, both the technical and organizational change must occur at the same time. This is to ensure that organization will not slip back to its old ways.

MAINTENANCE PLANNING AND SCHEDULING (MP&S)

Planning and scheduling is one of the fastest and most effective investments an organization can make to improve productivity and availability.Successful maintenance planning and scheduling programs require the disciplined application of proven processes and interdepartmental partnerships. It is important for departments that are influenced and impacted by the processes to understand the processes.

LEADERSHIP SKILLS FOR MAINTENANCE AND PRODUCTION TEAM LEADERS (LEADSKILLS)

This program is intended to train the front line supervisors and team leaders on how to evaluate and improve their staff performance. Every leader need to be able to effectively blend the value of achieving results with effective communication as well as strategic people management as part of efforts to maintaining achieving teams.

OPERATOR-BASED MAINTENANCE MANAGEMENT-7 steps to operator efficiency (AM)

This workshop will show how Operator Involvement and Skill Development play importantroles in improving equipment reliability. Spotting and responding to deterioration in equipment infancy can prevent breakdowns. About 65% of all breakdowns can be prevented by having the operator closest to the equipment clean, lubricate, and inspect on a regularly planned basis.

BEARING & BELT CONVEYOR MAINTENANCE (BBC)

Maintaining the power transmission components of a high capacity, high-power bulk material handing conveyor belt requires treating it as system. This training will expose the participants to the best maintenance practices for bearings and conveyors improve work safety and increase productivity.

RELIABILITY-CENTERED MAINTENANCE MANAGEMENT (RCM)

This training links reliable equipment and reliable process to relate with Reliability andMaintainability Design. In many organizations the waste in operations and maintenance systems is huge. The waste is defined as the difference between how good your performance could be and your current performance. MemCons will work with your team to maximize productivity and improve reliability in maintenance and operations practices.

OPERATING AMMONIA REFRIGERATION PLANT (AMREF)

This training has been design for refrigeration plant operators, Technicians and Engineers whoneed to be aware of the potential hazards associated with ammonia and the appropriate course of action that should be taken in an emergency. Ammonia is a toxic gas. Refrigeration plant operators, Technicians, Engineers and anyone working around the plant should be aware of the potential hazards and the appropriate courses of action to be taken in an emergency.

FUNDAMENTALS OF MACHINERY LUBRICATION (Greasing and Lubrication)

This course provides foundational training in industrial lubricants, machinery lubrication and oil sampling. It is designed to help participants achieve greater equipment reliability in their plant. If you aren’t using the correct lubricant at the right time in the right quantity and in the right place, you could be doing your equipment more harm than good.Modern lubrication programs have changed considerably from “old school” methods that have been passed down through generations.This course contains a strategic collection of the very best practices for applying and managing lubrication that you can take home and begin using right away.

TEAM BUILDING SKILLS FOR MAINTENANCE AND PRODUCTION TEAMS (TBS)

Team building is powerful tool to break down barriers and solve conflicts between employees.Team building activities creates a healthy bond within the team, it makes communication easy.Team bonding training breaks ice especially for new members in the team; it creates confidence in the team. Team building training gives an opportunity to the members to connect with their colleagues in different way, understand them personally and it helps them understand importance collaboration.

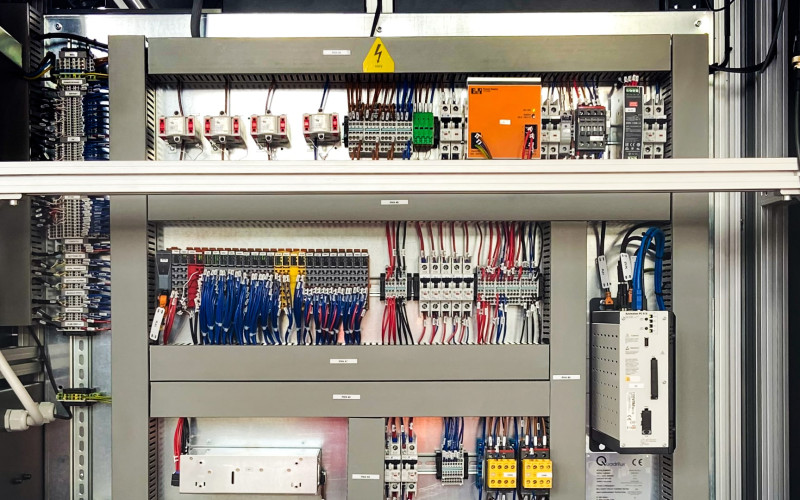

INDUSTRIAL CONTROL & AUTOMATION (PLC)

The PLC training program introduces participants to the concepts of PLCs and explains howthey can be used in a plant or manufacturing system. This training is designed such that even the first-time users can make a safe and quick start in getting to know the fundamentals of PLC programming. Our PLC training program is based on practical applications and experience in using programmable controllers in the workplace.

ELECTRICAL MOTORS AND CONTROLS MAINTENANCE (ELECM)

Most AC motors are started through a standardized control system designed to protect the motor, the circuit, and operating personnel. This training tool focuses on ladder diagrams, wiring, and troubleshooting techniques for the most common motor used in industry, the AC induction motor. Topics covered in this training include:

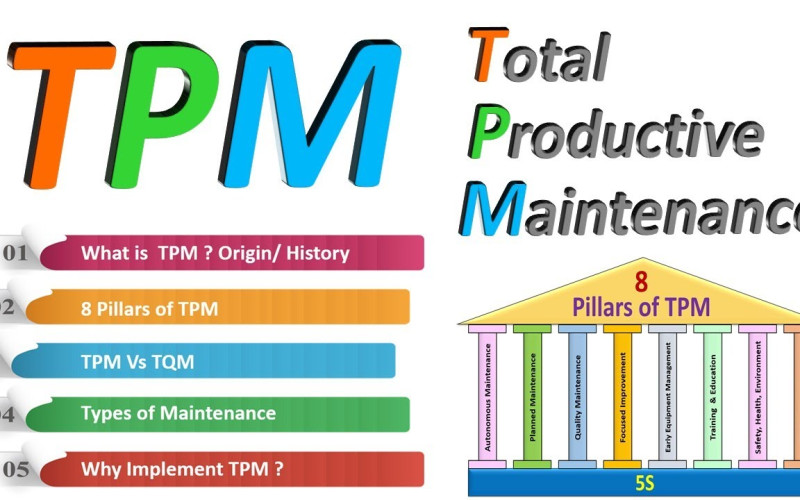

FOCUSED IMPROVEMENT (FI)

Focus Improvement (FI) is the engine of World Class Manufacturing (WCM) system and it isdriven by 5 indicators to manage improvements in any plant.Focus Improvement (FI) run as an integral part of the WCM TPM program within anorganization.

EFFECTIVE SUPERVISION AND DELEGATION TRAINING FOR TEAM LEADERS

Effective Supervisory Leadership Skills & Delegation Training gives you the skills that propel you to the next level of success.You will explore how to maintain technical expertise while demonstrating the right type ofleadership. This training will give you the personal, interpersonal and group skills to beinfluential in one-on-one situations, facilitate group performance and become an effective leader.Effective leadership performance depends on a blend of appropriate skills, knowledge, attitudes,and behaviors coupled with relevant experience. This training effective supervisory leadership skills and delegation helps supervisors gain the skills they need to become more effective leaders in your organization.

RELIABILITY-FOCUSED MAINTENANCE STOREROOM MANAGEMENT

Overview (3-day)Many planners and supervisors say that the largest issue they face in organizing maintenance work is “Finding materials and getting them to the right place at the right time”. Maintenance materials are a large part of any plant’s maintenance costs and not having the right materials in the right place at the right time is a common cause of productivity loss and reduced reliability. This unique event provides real solutions to maintenance Storeroom management problems.The goal is a common objective of maximizing plant reliability through logical and efficientmanagement of the spare parts and materials required by maintenance people.

SAFE MATERIAL HANDDLING AND WAREHOUSING

Material handling and warehousing provides a basic understanding of the major factors inmanaging a warehouse and distribution system. Introduces the concepts and applications for the effective management and control of distribution channel, warehouse, and transportation management functions and processes.This course is designed for people working in the fields of materials and/or operationsmanagement who need to learn the basic concepts, techniques, and terminology of warehousing and material handling activities in an organization. Techniques of material control, effective warehousing, and the use of appropriate material handling equipment are covered.

EFFECTIVE COMMUNICATION AND REPORT WRITING

Good communications and technical reports are often used as the basis to support criticaldecision-making within an organization, so the ability to communicate new ideas, information,proposals or recommendations efficiently and accurately to superiors and others is vital.Many production team leaders, supervisors, engineers and technical personnel lack confidence in their ability to communicate (write) about technical concepts and production ideas in a language that will be properly understood by the reader; yet the tools and techniques associated with this skill can be learned and developed.By attending this 3-day course you will learn, step by step, how to shape your thoughts and structure, draft and write clear and concise production/technical reports.

CONTINUOUS IMPROVEMENT (CI)

Continuous Improvement is both a mind-set and a range of techniques to review and evaluatework processes. As a mind-set, it is a way of approaching work so that a culture of innovation and creativity is encouraged throughout your plant. Continuous Improvement (Kaizen) is a system that involves every employee - from upper management to the cleaning crew. Continuous improvement is about setting clear goals (Maintenance, Production, Operations, Process, Sales, Marketing Customer Service etc.), having ways to measure progress toward those goals, refining goals and strategies based on those measurements and setting new goals over time to satisfy your customers.

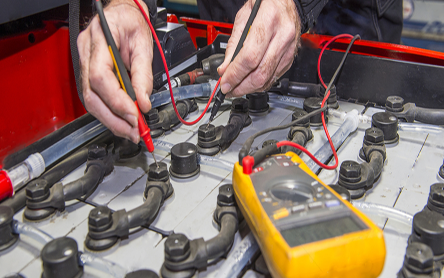

Battery Maintenance and Servicing Training

Battery Maintenance and Servicing Training aims to equip maintenance personnel with the best and the most appropriate maintenance practices to prolong and get the best performance from their batteries.The three-day (2) training consist of both theory and hands on approach to enhance reliabilityand productivity.

EFFICIENT ENERGY SAVING STRATEGIES TRAINING

This training on efficient energy saving strategies is specifically designed to intensify theawareness of presence of such strategies as well as emphasize the essence of effectivelyobserving and achieving a positive impact in the industry. This training takes the steps inidentifying energy efficiency opportunities while taking into consideration specific needs andbudgetary requirements. The workshop of practical exercises, techniques, guidelines, andinformation will enable the participants to develop consistent, useful, and relevant measures in energy audit and cost-saving energy management solutions.

SAFE WORK IN CONFINED SPACES AND AT HEIGHT, Code of Practice, Regulations and Guidance

A number of people are killed or seriously injured in confined spaces and working at height each year in various industries. This happens in a wide range of industries, from those involving complex plant to simple storage vessels. This training contains an Approved Code of Practice (ACOP) and guidance on the duties in the Confined Spaces and Height. Regulations which are applicable across all industry sectors and which apply to working in confined spaces and at height.

HEALTH AND SAFETY RISKS MANAGEMENT Code Of Practice, Regulations &Guidance

This Code of Practice on how to manage work health and safety risks is an approved code ofpractice under section 274 of the Work Health and Safety Act. An approved code of practice is a practical guide to achieving the standards of health, safety and welfare required under the WHS Act and the Work Health and Safety Regulations. This training offers participants a step-by-step method of assessing any health and safety risk and how to manage it effectively.

PACKAGING AND PRODUCTIVITY IMPROVEMENT TRAINING (P&PI)

Materials Packaging & Handling is concerned with movement of product from Production line to the Stocking point that ensures damage free movement of the product and it’s conducive to efficiently reduce cost and improve quality, through effective handling and focus improvements. This course has been specifically designed to enlighten supervisors who are involved in decision and implementation strategies to empower the workforce (personnel) to achieve long term change.

INDUSTRIAL PUMP REPAIRS AND MAINTENANCE

Pump Operation and Maintenance Training course is a detailed examination of common pump applications, pump selection, operations, troubleshooting, and maintenance. Individuals in pump and piping system industries will find this course a valuable asset for learning proper pump operation and understanding typical pump behavior. Pump Operation and maintenance training gives you a thorough understanding of your equipment and the operated systems. Trained staff with the requisite skills will improve safety and standardized work practices, while reducing your maintenance costs over the lifetime of the equipment. Pump Operation and Maintenance Training will provide attendees with the practical knowledge and skills needed to address common concerns of pumps and pump systems.

INDUSTRIAL SAFE WORK (ELECTRICAL AND CHEMICAL) Code Of Practice, Regulations & Guidance

The training is to achieve implemented systems and used as Code of practice,Regulations and guidelines to provide practical guidance on measures that may be put in place to reduce the incidence of occupational injury and disease in the industry due to electrical work and chemicals.

MAINTENANCE OF BOILER MACHINES

This course is designed primarily for Boiler Operators, Maintenance Staff, Plant Technicians and engineers. This an intensive course designed to provide a thorough grounding in the everyday operation and maintenance of boilers, burners and boiler auxiliary equipment. The course also covers all relevant Health and Safety issues, fault identification and emergency situations. The ultimate aim of the course to make sure that the plant can be operated safely, efficiently and economically.

FORKLIFT OPERATOR TRAINING

Operating a forklift requires skill, training, and experience. Although it may seem as easy as driving a car, there are many factors that make driving a forklift much more difficult. Learning how to operate a forklift safely can help to prevent accidental injuries and possible death. The goal of forklift training is to help you achieve a work environment that is accident free and meets SAFETY regulations. Participants will receive training on the safe working practices applicable to forklift operations and sufficient practical training to ensure the operator is conversant and comfortable with the operating of the machines in a work environment

TROUBLE SHOOTING AND MAINTENANCE OF AIR-CONDITION AND REFRIGERATION SYSTEM

Troubleshooting and Maintenance of Air-conditioning and Refrigeration system workshop hasbeen designed to enhance the knowledge of engineers and technicians on various methods and procedures of troubleshooting Ref and AC systems to eliminate frequent breakdowns and to improve productivity.

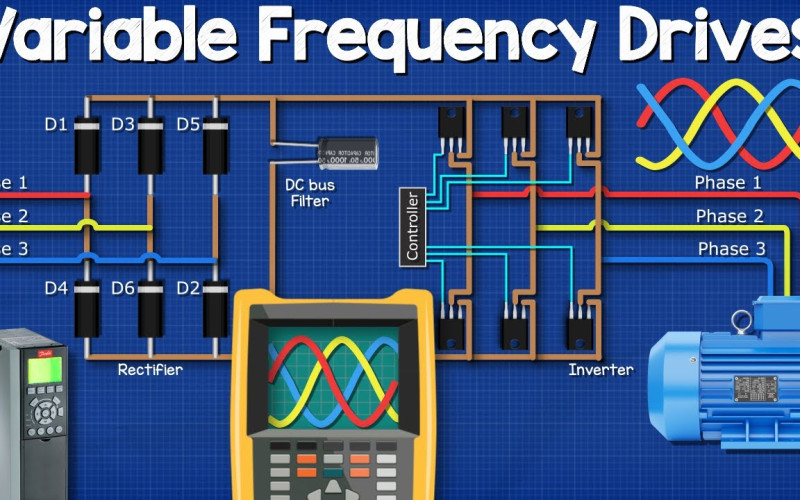

VARIABLE FREQUENCY DRIVES (VFDS)

Introduces the participants to the world of variable frequency drives and their applications in industrial plants. Participants will learn how to improve VFD control and efficiency, and fix VFDs, reduce equipment downtime, and eliminate chronic VFD problems and perform hands-on activities with a real-life variable frequency drive. Participants will input motor data into the variable frequency drive, set parameters for speed control and over current protection, and check fault codes.

HUMAN MACHINE INTERFACING (HMI) AND NETWORKING TRAINING

HMI and Networking Training is an intensive program focusing on Human MachineInterface (HMI), Man Machine Interfacing (MMI), and industrial networking. The courselays emphasis on developing and building a solid foundation on HMI. HMI can provide agraphical view and control over various process parameters involved in an IndustrialControl Process (ICP). From operator's perspective HMI is an eye into process information across every type of applications in an industrial environment.Participants will develop the skills for fault diagnostics, troubleshooting, and interfacingwith PLC. This skill-building training program will impart the knowledge and skills to work with PLC and understand wiring of different filed devices to PLC. Various network topologies, ports, drivers, and associated hardware information is shared to implementhuman machine interfacing HMI.

DEPOT OPERATIONS

Designed for personnel working in the petroleum depot operations seeking to acquire moreknowledge on effective handling of depot operations, storage, design standards, depotautomation and warehouse control. It has been critically designed to address performancechallenge in the various segments of the corporate value chain using new approaches that will insight a new thinking of resolving depot operational complexities.Training ObjectivesAt the end of this training seminar, you will learn to: * Understanding the various functions within a petroleum depot* Understanding the principles governing depot operations* Stocks taking, Accounting and control* Product receipts and transfer, custody transfer* Tank farm operations, calibration and management

PROPER USAGE & MAINTENANCE OF PERSONAL PROTECTIVE EQUIPMENTS (PPE´s)

Personal protective equipment (PPE) is an important means of preventing work injuries. Ideally,the best approach is to maintain a safe work environment and eliminate any potential hazards. PPE should only be relied upon as a last line of defence in places where it is not practicable to control the hazards at source. The use of PPE generally implies working in a potentially hazardous work environment and its use is a major means of injury prevention. Therefore, it is of prime importance to ensure that the equipment chosen is both reliable and effective, it is being properly used and maintained, and the user has undergone adequate training. The aim of this Training is to raise the awareness of occupational safety and health practices and the proper use/maintenance of PPEs of people from all occupations.

IMPROVING PRODUCTIVITY AND RELIABILITY THROUGH INTER- DEPARTMENTAL PARTNERSHIP

Meeting or exceeding productivity requires the disciplined implementation of processes andinterdepartmental commitment. It is important for departments that are influenced by theprocesses to understand the entire processes and commit to sustaining winning workingstrategies. The impact of each department and the teaming for a common goal is the key (theVision and the Mission of the Organization).

TOTAL PRODUCTIVE MAINTENANCE MANAGEMENT (TPM)

The success of every organization depends on how all stakeholders positively influences productivity. TPM builds synergistic relationship among all organizational functions, but particularly between operations, production and maintenance, for continuous improvement of product quality, operational efficiency, capacity assurance and safety

INDUSTRIAL PNEUMATICS TRAINING (IND-PNE)

by breaking down the components of the pneumatic system,Participants will design, construct, adjust, and analyze circuitsleaving with valuable new skills that can be successfully applied totroubleshooting major components, eliminating the “trial and error”methods through a systematic approach. Using circuit diagrams,participants will learn how to determine the root cause of chronicand persistence problems to accomplish a desired result.The goal of this training is to provide participants with a solidunderstanding of the concepts associated with Pneumatic equipmentas found in industry today.

INDUSTRIAL HYDRAULICS TRAINING (IND-HYD)

The practical applications of fluid power equip your team to gainunderstanding of the symbols used to construct circuits fromschematic diagrams.The goal of this training is to provide participants with a solidunderstanding of the concepts associated with Hydraulic equipmentas found in industry today. It also provides a closer look atnumerous industries and their specific applications for Hydraulic, aswell as a thorough guide to troubleshoot equipment troubles usingthe circuit/schematic diagram to determine the root cause of chronicand persistence problems to accomplish a desired result.

Our Business Values

1RESPECT

To value, appreciate and acknowledge all stakeholders including employees, clients, partners, investors and the community.

2INTEGRITY

To walk the talk of honesty and reliability

3TEAMWORK

Diverse efforts and resources agreeing to a accomplish common goal.

4INNOVATION

With continuous improvement, we continually adapt best practices in technology and creativity in meeting clients needs

5PRODUCTIVITY

To continuously work at performance improvements.

6DELIVERY

To discover what's important to stakeholders and exceed expectations.

7SUSTAINABILITY

To drive positive change and maintain world class standards.

Newsletter - Get Updates & Latest News

Get in your inbox the latest News and Offers from